Epoxy Coatings

Leading Manufacturers, Wholesaler, Exporters, Retailer and Distributor of Acid Proof Paint, Anti Magnetic Coatings, High Build Coaltar Epoxy Coatings, High Build Finish Epoxy Coatings, Phenolic Epoxy Coatings, Self Priming Epoxy Coatings, Solvent Free Epoxy Coatings and Solvent Less Epoxy Coatings from Surat.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Distributor |

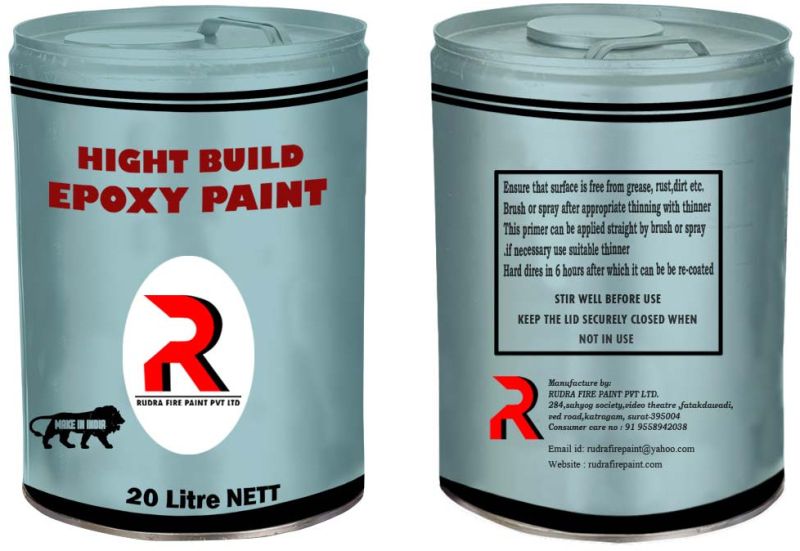

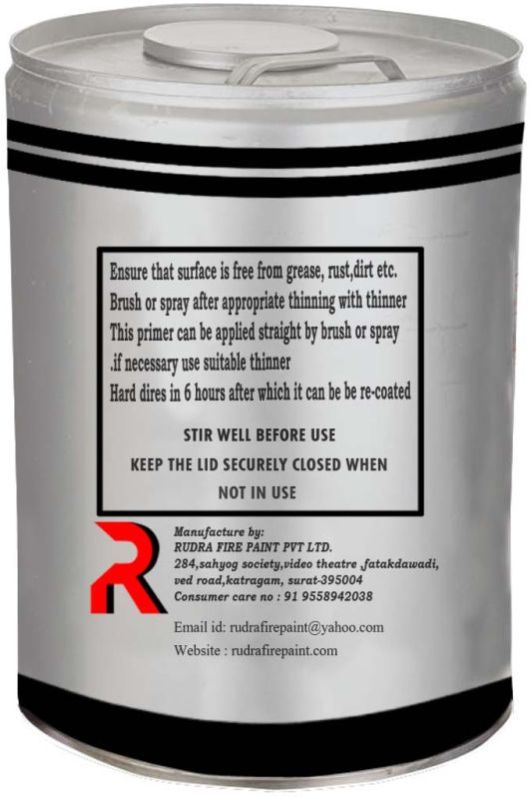

| Packaging Size | 20-25 L |

| Packaging Type | Can |

| Certification | ISO9001:2008 |

| Style | Spray |

| Speciality | Acid Resistant, Anti Corrosive |

| Application | Brush, Roller, Spray Gun |

| Form | Liquid |

| Color | Anyy |

| Product Code | RP-604 |

| Port | Navasova mumbai |

| Payment Terms | L/C, D/A, Other |

| Delivery Time | 3 to 4 days |

| Packaging Details | 20ltr centenar |

Acid resistant paint is a specially formulated coating designed to protect surfaces from corrosive damage caused by exposure to acids, alkalis, and harsh chemicals. Ideal for industrial, commercial, and laboratory environments, this paint creates a durable barrier that resists chemical reactions, preventing surface degradation and extending the lifespan of equipment and structures. Typically made with epoxy, polyurethane, or vinyl ester resins, acid-resistant paint offers excellent adhesion, high mechanical strength, and resistance to abrasion and moisture. It is commonly applied to concrete, metal, and masonry surfaces in facilities such as chemical plants, wastewater treatment plants, and battery rooms. In addition to chemical resistance, many acid-resistant coatings also provide protection against heat and UV exposure, making them suitable for both indoor and outdoor applications. Easy to apply using brushes, rollers, or spray equipment, acid-resistant paint ensures long-term performance with minimal maintenance, helping to maintain safety and compliance in demanding operational environments.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Distributor |

| Size | 20 kg |

| Application | spry, brush ,roller |

| Brand Name | RUDRA PAINT |

| Form | SURAT,GUJARAT |

| Classification | Tow Pack |

| Purity | 99 % |

| Product Code | RP-620 |

| Port | Navasova mumbai |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union |

| Delivery Time | 3 to 4 days |

| Packaging Details | 16 + 4 cantener |

An anti magnetic coating is a specialized layer applied to materials or components to shield them from the effects of magnetic fields. This coating is essential in industries such as electronics, aerospace, watchmaking, and precision engineering, where magnetic interference can disrupt functionality or accuracy. Typically made from non-magnetic or diamagnetic substances such as titanium, ceramic composites, or special polymers, the coating works by blocking or redirecting magnetic flux. It prevents the induction of currents and minimizes magnetic attraction, thereby maintaining the integrity and performance of sensitive instruments. In wristwatches, for example, anti-magnetic coatings protect the movement from magnetic fields encountered in daily life, which could otherwise cause timekeeping errors. Similarly, in electronic devices, such coatings help safeguard data storage and signal clarity. The development of advanced anti-magnetic coatings continues to improve durability, thinness, and effectiveness, enabling their integration into compact, high-performance devices operating in magnetically active environments.

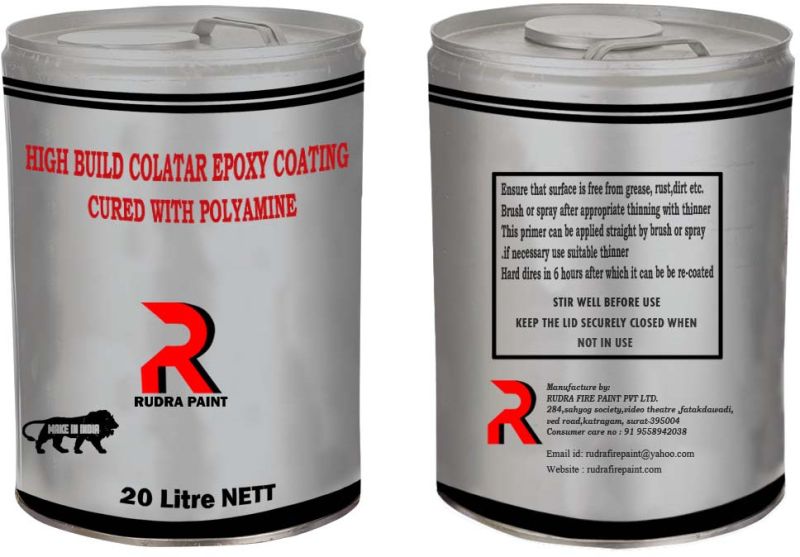

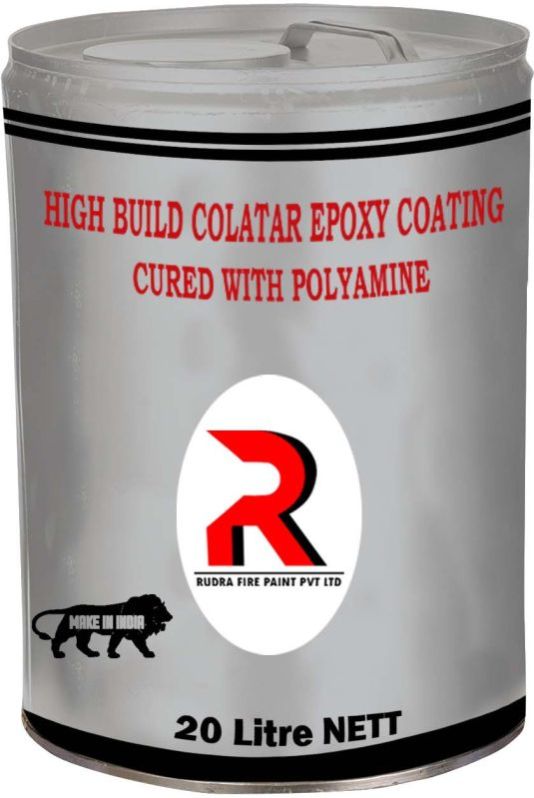

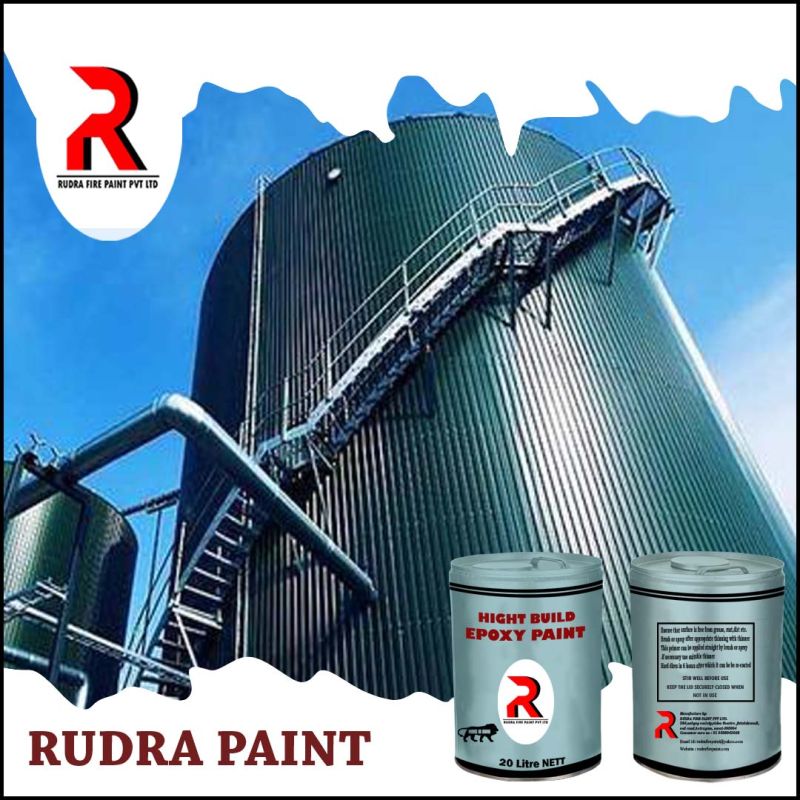

| Business Type | Manufacturer, Supplier |

| Color | Available in Many Colors |

| Form | Liquid |

| Usage | Industrial |

| Purity | 100% |

| Shelf Life | 1Year |

| Country of Origin | India |

| Product Code | RP 310 |

High-build coal tar epoxy coatings cured with polyamine are thick protective coatings used on surfaces. They consist of coal tar, epoxy resins, and a polyamine curing agent. The coatings are applied in multiple layers using brushes, rollers, or sprayers. They provide excellent chemical resistance, waterproofing, and abrasion resistance. High-build coal lar epoxy coatings are commonly used in industrial and marine applications. Proper surface preparation and safety precautions are important during application and curing.

| Business Type | Manufacturer, Supplier |

| Color | Available in Many Colors |

| Form | Liquid |

| Usage | Industrial |

| Purity | 100% |

| Shelf Life | 1Year |

| Country of Origin | India |

| Product Code | RP 308 |

Ahigh-build epoxy finish coating is a thick and durable protective coating composed of epoxy resins and a polyamine curing agent. It provides excellent adhesion, chemical resistance, and protection against abrasion and impact. The coating is applied in multiple layers using brushes, rollers, or sprayers and undergoes a chemical reaction during curing, forming a strong, cross-linked network. High-build epoxy coatings create a substantial film thickness, ranging from 10-40 mils or more. They offer advantages such as adhesion to various substrates, chemical resistance, abrasion resistance, and a smooth finish. Proper surface preparation is essential, and safety precautions should be followed during application and curing.

| Business Type | Manufacturer, Supplier |

| Color | Available in Many Colors |

| Form | Liquid |

| Usage | Industrial Use |

| Purity | 100% |

| Shelf Life | 1Year |

| Country of Origin | India |

| Product Code | RP 316 |

Two-component epoxy phenolic coatings with a polymine adduct system are protective coatings used in specific applications. They consist of epoxy resins, phenolic resins, and a polymine adduct curing system. These coatings offer excellent chemical resistance, high temperature resistance, and durability. They are applied using spray equipmenotr brushes/rollers, with the two components mixed together before application. The polymine adduct system iniliates a chemical reaction, resulting in a hard, cured coating. Proper surface preparation is crucial, and surfaces should be clean and free from contaminants.

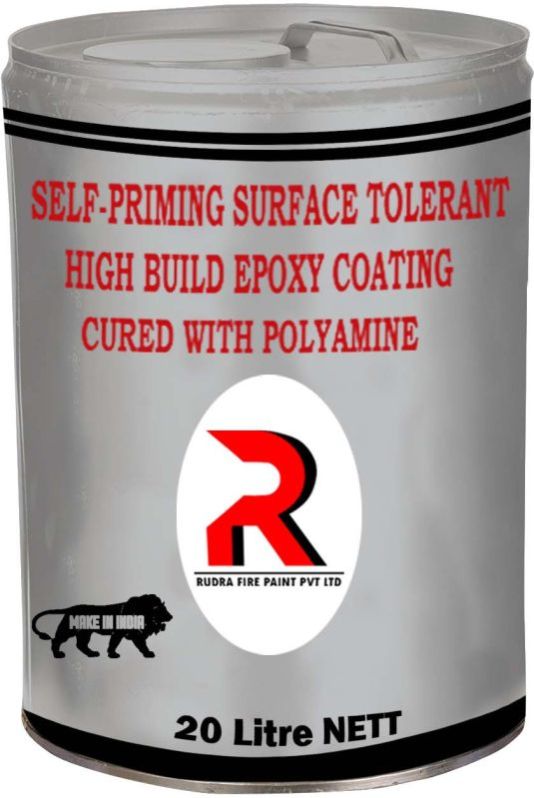

| Business Type | Manufacturer, Supplier |

| Color | Available in Many Colors |

| Form | Liquid |

| Usage | Industrial |

| Purity | 100% |

| Shelf Life | 1Year |

| Country of Origin | India |

| Product Code | RP 311 |

Self-priming surface tolerant high-build epoxy coatings cured with polyamine are durable coatings that adhere well to various surfaces without the need for a separate primer. They can be applied using brushes, rollers, or sprayers and offer excellent adhesion, corrosion resistance, and durability. These coatings can be applied to surfaces with less-thanperfect conditions and have a curing process initiated by a polyamine curing agent. Proper surface preparation and safety precautions should be followed. Always refer to the product's technical data sheet and manufacturer's recommendations for best results.

| Business Type | Manufacturer, Supplier |

| Color | Available in Many Colors |

| Form | Liquid |

| Usage | Industrial Use |

| Purity | 100% |

| Shelf Life | 1Year |

| Country of Origin | India |

| Product Code | RP 317 |

Two-component solvent-free high-build epoxy phenolic/novalac coalings are protective coatings that offer high chemical resistance, durability, and heat resistance. They consist of epoxy resins, phenolic or novalac resins, and a hardener. These coatings are applied using brushes, rollers, or spray equipment in multiple layers to achieve a thick build. The hardener initiates a chemical reaction, resulting ina cross-linked and cured coating. They are commonly used in industries such as oil and gas, chemical processing, and storage tank linings. Proper surface preparation is important, and safety precautions should be followed during application.

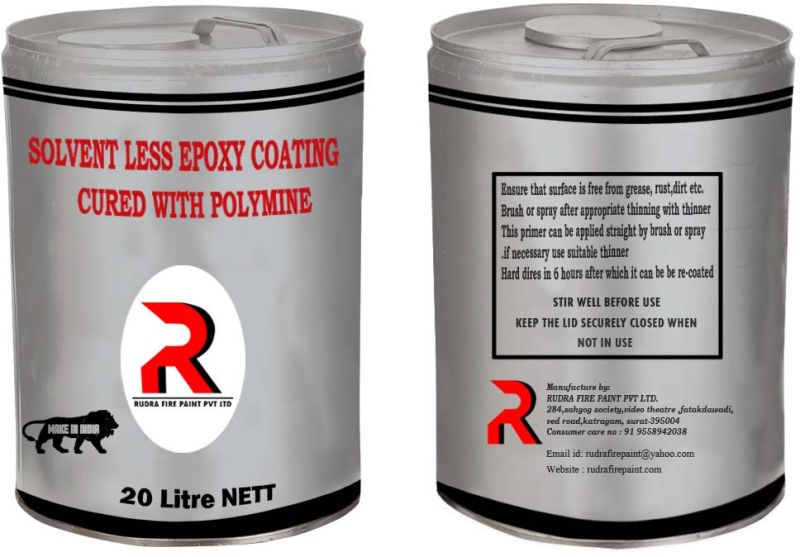

| Business Type | Manufacturer, Supplier |

| Color | Available in Many Colors |

| Form | Liquid |

| Usage | Industrial |

| Purity | 100% |

| Shelf Life | 1Year |

| Country of Origin | India |

| Product Code | RP 309 |

Solvent less epoxy coatings cured with polymine are protective coatings that do not contain solvents, They are composed of epoxy resins and a polymine curing agent. These coatings are applied using specialized equipment and undergo a chemical reaction when the epoxy resin and polymine are mixed together. They offer benefits such as high chemical resistance, excellent adhesion, and durability. Proper surface preparation is important, and safety precautions should be followed during application and curing.